E71T-1C/M is tubular flux cored wire used usually with flux cored arc welding process FCAW with and without shielding gases depending on the wire designation. This type of welding wires is manufactured in the form of coils.

What does E71T-1 stand for?

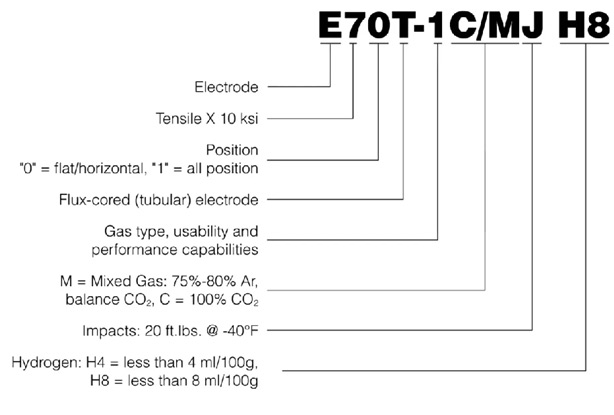

The E71T-1 flux cored welding wire designation is according to the American welding society standard specification AWS SFA 5.20 “SPECIFICATION FOR CARBON STEEL ELECTRODES FOR FLUX CORED ARC WELDING”. This wire designation is taken from the general wire designation mentioned in the previously mentioned specification and the general designation takes the form of EXXT- XX – J X H X in which each part refers to certain information as follows:

So, in our case of welding electrode E71T-1C/M, each part in the designation starting from left to right is explained as follows:

• E: stands for welding electrode.

• 7: refers that the produced weld metal has minimum ultimate tensile strength of 70,000 psi provided that the specified shielding gas is used but in case of using shielding gas other than the specified one, you have to contact the manufacturer.

• 1: refers that the electrode is used in all welding positions except for vertical down.

• T: refers that the welding electrode is in tubular form and cored with flux.

• 1: this number refers to the usability of the electrode with requirements for polarity and general operating characteristics. This digit in the welding electrode designation may take numbers starting from 1 to 14 or letter “G” or “GS” where “G “refers that the usability requirements are not specified and “S” refers that this electrode is to be used for single pass welding. in our case, “1” refers to the electrode that can be used with DCEP. Here below is a table taken from AWS SFA 5.20 showing the usability numbers.

• C/M: this digit in the designations stands for the shielding gas requirements where “C” stands for 100%Co2 and “M” stands for mixture which may be 75-80% Ar and balance is to be Co2.

There are some digits that may be added to specify certain requirements as follows:

• J: refers to the impact characteristics of the produced weld metal provided that the other requirements of usability and shielding gases are applied.

• HX: refers to the amount of moisture present in the produced weld metal provided all other requirements of shielding gases and usability are applied where “X” refers to X ml/100 g of produced weld metal.

What are the benefits and types of flux in the wire core?

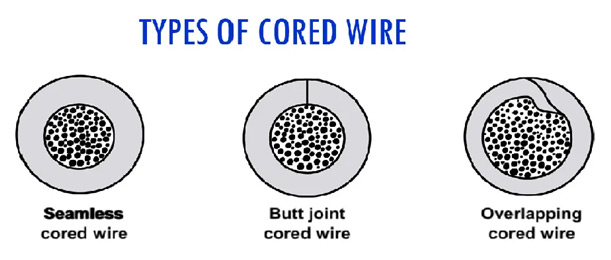

The flux cored wire contains flux in the core and it has three types: seamless wire with flux in the core, Butt joint cored wire and overlapping cored wire.

Flux in the cored wire plays an important role in welding process and has the following benefits:

• Serves as current transfer during welding.

• Stabilize the arc.

• Add alloy elements.

• Produce gaseous shield.

• Produce slag which enhance weld quality and cleanliness.

• Add iron powder to increase the deposition rate.

The flux in the flux cored wire has the following types:

• Rutile flux: this type is characterized by high efficiency due to the ease of slag detachability, minimum spatter, is used for single and multiple pass welding, is used with 100% Co2 and can be used with Ar+Co2 mixture to improve current transfer and decrease spatters.

• Basic flux: this type of flux contains fluorides and alkali metal oxides. This type of flux is used to have welded metal with high impact/toughness properties in addition to high resistance to cracking.

• Metallic powder: the flux in this type consists of alloys and iron powder to allow high speed fusion welding without getting lack of fusion. Wires of this type of flux are characterized by shallow penetration.

Applications of welding wire E71T-1C/M

E71T-1C/M is a gas-shielded carbon steel wire for fabrication of mild and low carbon steel; structural and pressure vessel grades. This type of flux cored wire can be used in the following applications:

• Ship building.

• Bridges.

• General fabrication works.

• Storage vessels and tanks.

• Boilers fabrication.

• Structural steel fabrication and erection.

What is the difference between E71T-1C/M and E71T-GS?

As mentioned before in explaining the usability numbers in the wire designation, the “GS” in the wire designation E71T-GS refers to the fact that the usability of wire is not specified including polarity and shielding gases in addition to the fact that this wire can be used for single pass welding.

AWS A5.20 Class E 71T-GS

E71T-GS is self-shielding flux cored wire for single pass all-position welds on mild steels used for field construction, erection and repair. It is often used for fabrication of mild steel sheet metal where secondary shielding gas is not practical.